The Main Principles Of Sheroz Earthworks

The Main Principles Of Sheroz Earthworks

Blog Article

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Table of ContentsThe Buzz on Sheroz EarthworksA Biased View of Sheroz EarthworksWhat Does Sheroz Earthworks Mean?An Unbiased View of Sheroz EarthworksSheroz Earthworks - An Overview

For any earthwork service provider, it is essential to execute work with high quality, precision, and on routine. Making use of machine control in job equipments allows optimizing the various phases in the earthwork process, from intending to the upkeep stage - trimble repair parts. The device control system helps the device operator in achieving the target airplane quickly and conveniently

The device control system guides the driver with centimeter precision. Remote support conserves time and money, as it decreases downtime in jobsites.

How Sheroz Earthworks can Save You Time, Stress, and Money.

Our system's parts are very carefully designed to withstand the harsh conditions of building and construction sites. Comparison of the exact same job performed utilizing equipment control versus the standard technique reveals that, on standard, the conventional technique needs 50% more time to accomplish the same job as the technology-assisted approach.

Seems excellent? Go into the Xsite device control system; it's right here to give you with a considerable advantage when dealing with earthmoving equipment. Discover how Xsite Device Control can boost your efficiency and make certain work safety! We recognize that finding out a new modern technology could seem like a drag, yet don't stress! Our pleasant and professional regional support solutions have actually got you covered, ensuring that you can maintain working smarter without disruptions while at work! Via remote assistance, your local Xsite supplier can supply support or troubleshooting without needing to see the site! What sort of excavators does machine control fit? Xsite Device Control systems can be set up to any kind of excavator from mini excavators to large mining excavators.

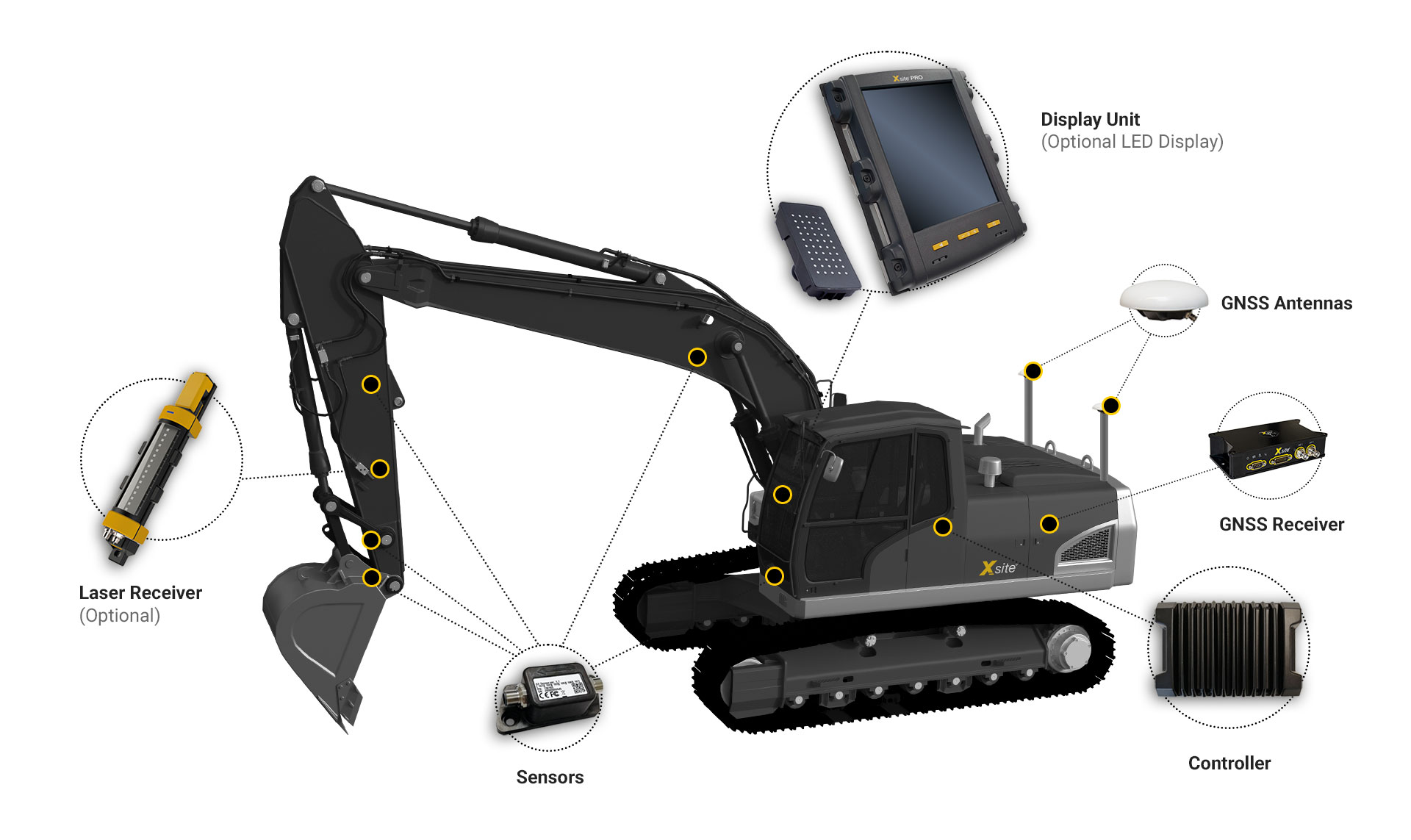

Exactly how does maker control job? In 2D systems, the device is equipped with calibrated disposition sensing units. These sensing units are mounted on the pre-determined parts of the equipment in excavators the sensor are usually placed to the frame, boom (or booms), digger arm and to the quick coupler - topcon gps. By utilizing the information received from these sensors the system can calculate the specific position of the excavators bucket tip in relevance to a referral point.

The system is extremely easy to discover the essentials can be educated in under one hour of training. How does the remote support job? A cordless web connection makes it possible to establish a remote link in between the maker control system and the solution.

Sheroz Earthworks for Dummies

What kind of information layouts Xsite systems support? Xsite Equipment Control systems sustain open standard file styles, enabling seamless details flow from one system to another. Supported documents formats: 2D-Maps: DXF Point documents: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Versions: DXF, XML What components are set up on my equipment? Depending upon your selection of system (with or without placing, i.e - trimble tripod parts., 2D or 3D), your machine is equipped with inclination sensors, a controller system, and a display/operating panel.

Lots of equipment and software application solutions exist to help figure out a device's present setting on the planet and compare it with a wanted design surfaceand construction drivers can do even more to take advantage of the benefits. Machine control is making use of different positioning sensors and a screen to supply the driver with a reference in between the position of the container or blade and the target grade.

Depending upon the setup, equipment control systems can give the driver with a basic aesthetic overview to bucket or blade setting, or can instantly move the blade to grade by speaking with the equipment's hydraulics - https://www.reverbnation.com/artist/sherozearthworks. There are maker control systems readily available for practically any kind of device: graders, dozers, excavators, dirt and asphalt compactors, scrapers, leaners, grating devices, and pavers

Sheroz Earthworks Can Be Fun For Anyone

Some you could try here advantages consist of lowered rework, improved task efficiency, and lower checking costs. Machine control can likewise assist increase productivity and decrease general prices. This technology is transforming the method the construction industry works. Building equipment without machine control will certainly come to be a distant memory and the advantages obtained from it will be many.

Trimble equipment control systems provide a myriad of benefits to anybody who utilizes earthwork machinery and, at EarthCalc, we can provide you with 3D declare your maker control-enable devices. Unsure if equipment control deserves the price? Consider the following factors why you require to consider this option.

Using general practitioner straightened with your 3D layout data, these systems virtually assure that you will certainly eliminate or position the right quantity of material at the building site. On many building websites, rework is an usual and irritating reality, but with Trimble machine control, you can get rid of the demand for rework.

The 10-Second Trick For Sheroz Earthworks

Frequently, with Trimble machine control, you can get rid of excess devices at a details work website. For instance, a work that could have needed making use of three or four items of excavating equipment currently might need only two items of equipment to accomplish the exact same task in less time. This enables you to move your devices to an additional task site and deal with numerous tasks at one time.

Report this page